Vipshop

Seuic AUTOID 3 mobile computer is equipped with a unique scanning engine, meeting the client's various barcode needs. For closely spaced barcodes, our precise targeting feature perfectly addresses the client's challenges. The device's unique PA design ensures excellent signal strength, roaming, and reconnection capabilities, making it ideal for mobile picking operations in complex warehouse environments.

Daikin Air Conditioning

Daikin Air Conditioning's warehouse management utilizes the Q7 Grip long-range handheld mobile computer, which connects in real-time to the WMS (Warehouse Management System) platform via the network. This allows real-time updates of warehouse and personnel management data, significantly improving operational efficiency.

Erdos

Using the Seuic AUTOID UTouch RFID reader, Erdos streamlined operations like store inventory counting, product locating, and receiving. The device allows for fast, bulk reading of all product details within a box, eliminating the need to individually scan barcodes for each item.

ANTA

Anta Group adopted advanced RFID readers and mobile computers to provide efficient frontline support in its stores.

Bridgestone

Seuic mobile computers, with their highly reliable industrial design, are capable of withstanding high-temperature environments. Equipped with a high-performance Wi-Fi module and proprietary algorithms, mobile computers resolve Wi-Fi roaming issues in steel-structured shelving areas. The solution has been successfully implemented in high-temperature workshops and warehousing operations, enabling paperless workflows.

Midea

Seuic mobile computers were deployed to handle Midea's warehousing operations such as inbound/outbound, inventory counting, returns, and workshop reporting, ensuring the seamless integration of smart production. This provides precise terminal data for intelligent production and plays a crucial role in omni-channel traceability.

XCMG

Mobile computers are used in various stages of warehouse and production operations, solving the time-consuming issues of manual record-keeping. This shift to a paperless, digitalized system enhances overall efficiency and productivity.

Mindray Medical

By using mobile computers in various scanning processes across production and warehousing, along with customized inventory software to achieve full process digitalization, Mindray Medical has addressed the challenges of manual data entry and improved operational efficiency.

Soufeiya Home

Reduce the time spent on manual scanning and data entry, minimize production line downtime, and enhance overall productivity by Seuic X4 fixed barcode scanner.

Aiko Solar

SEUIC professional DPM mobile computer has AI+DPM algorithm, which can efficiently read graphite DPM codes and increase scanning efficiency by 30%.

ZENITH

Each operator is responsible for a specific production machine. By using the Seuic mobile computers, operators can record the wet drawing trays and machine numbers for each production cycle. After production, packaging is associated, and the entire batch is stored in inventory. This data collection process (scanning) provides a basis for future production traceability.

NISCO

The Seuic AUTOID Q7-(Grip) mobile computer is used in NISCO's storage operations. Its unique long-distance scanning capability, with a range of up to 15 meters, fully meets the steel industry's needs for long-distance code reading and enhances warehouse operational efficiency.

TW Solar

By introducing the Seuic CRUISE2 mobile computers, the system can sequentially scan module codes, product nameplates, and machine codes, integrating with the client's MES system to determine pass/fail status, thus minimizing errors in SN number comparison due to manual operations.

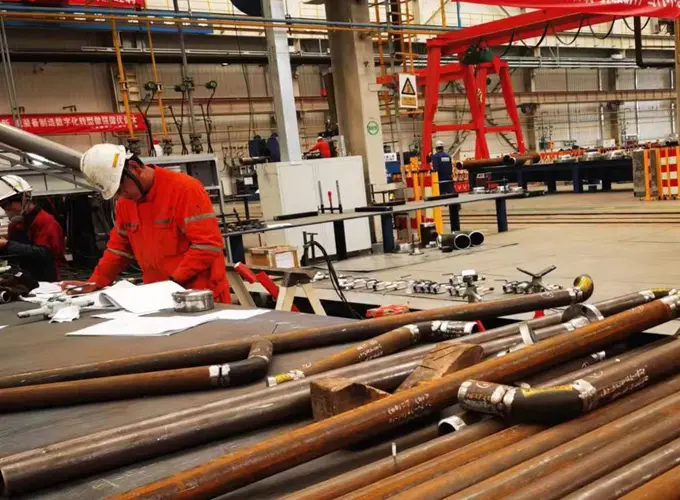

Offshore Oil Engineering

During welding operations, connect a UHF module to a 5G industrial tablet via its Type C port to expand the RFID functionality of the tablet. This facilitates the input and verification of material numbers in the business process, standardizes process management, and digitizes production data.

Jomoo Bathroom

The Seuic AUTOID Q7-(Grip) mobile computer is designed specifically for vertical warehouse scanning, offering a long-range scanning capability of up to 15 meters. Employees do not need to dismount for scanning. Its unique PA design ensures excellent signal strength, roaming capability, and reconnection performance, making it ideal for high-rise vertical warehouses. The 110dB volume ensures clear scanning even in noisy environments.

Yili Milk

Utilizes Seuic OCR recognition technology with deep learning models and post-processing methods to address issues such as adhesion, multi-box, and interference.

Seuic's custom OCR algorithms can recognize printed characters on various background colors, enabling rapid data collection and entry.

Yonghui Supermarket

By using Seuic products can real-time tracking to optimize order completion rates and inventory accuracy, reduces material handling costs while improving compliance, safety, and operational efficiency.

Haojue Suzuki

By using fixed RFID readers to automatically read RFID tags, the system monitors and records the manufacturing status of products at each production stage. Operations such as RFID information reading, writing, and binding are performed at appropriate workstations, enabling traceability of production process quality.

AKM MEADVILLE Electronics

With X5mini industrial vision barcode scanner in automation production lines, it improves maintenance efficiency by 50%.

Kao

Kao (Shanghai) Factory started operation in 1993 , mainly producing shampoo, conditioner, hair care products, skin care products, liquid detergents, etc. Kao ranked 132nd in the 2018 World 's Top 500 Brands . On May 13 , 2020 , Kao ranked 604th on the 2020 Forbes Global 2000 list .