Brief Introduction

Global manufacturing is turning to an intelligent, digital and automated production model. As the key to intelligent production, the application of 5G network technology has become an important trend in the manufacturing industry. Based on this, Seuic 5G industrial tablet came into being and quickly entered many manufacturing companies.

With the characteristics of high reliability, strong performance and large-screen mobile operation, Seuic 5G industrial tablet helps enterprises to realize flexible organization and scheduling in the production process, which greatly improves the production efficiency of enterprises and reduces operating costs. Seuic 5G industrial tablet can be combined with other equipment to provide enterprises with greater production assistance!

Application 1: Billboard in the production process (products used: 5G industrial tablet & barcode scanner)

Customer case: a large machinery manufacturing company

Customer pain points:

1. The working environment is complex, it is difficult to connect devices stably, and the safety requirements are high.

2. Manual input of material information by workers is inefficient and error-prone.

Application details:

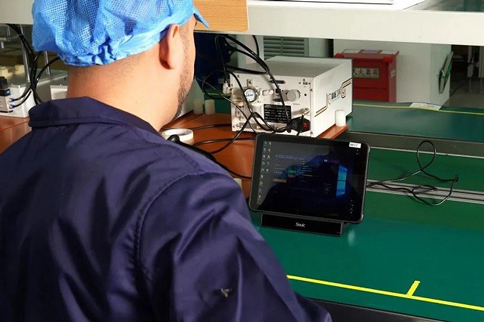

Seuic 5G industrial tablet is used on the wall through a fixed bracket, and the high-definition large screen can view data and operate the MES system; at the same time, the tablet is connected to a scanner to collect material data.

Application advantages:

1. Device connection is safe and stable: 5G network can carry more device connections, and Seuic 5G industrial tablet provides high-speed data transmission; with Android12 system, the security is higher.

2. Improve efficiency and reduce errors: 5G industrial tablet are equipped with barcode scanners, and workers use barcode scanner to collect data. Compared with manual input, it can improve efficiency and accuracy.

3. Realize real-time remote management: 5G industrial tablet can realize remote management inside and outside the factory. Through corresponding software and systems, remote monitoring, controland adjustment of equipment can reduce labor costs.

Application 2: Welding records in theproduction process (products used: 5G industrial tablet & RFID module)

Customer case: a large state-owned industrial enterprise

Customer pain points:

1. The information recording of weldingmaterials is cumbersome and time-consuming.

2. Workers need to view drawing tutorialson a large screen.

3. 5G network transmission requirements.

Application details:

Workers use Seuic 5G industrial tablet toview tutorials and use it with RFID modules. The usage of welding parts can be recorded in real time.

Application advantages:

1. Non-inductive data collection: Using RFID products to connect industrial tablet can free hands and realize "non-inductive" material data collection during operations.

2. View drawings on the large screen: Through the large screen of Seuic 5G industrial tablet, the drawings can bed is played more clearly and accurately, and can be updated in real time, and can be issued simultaneously with one key.

3. Improve production quality: 5G industrial tablet can conveniently collect and transmit various production link data, and analyze these data to reduce defects and waste in the production process and improve production quality.

In addition to the application of the above combined operation methods in the production process, Seuic 5G industrial tablet can also be used in factory automation and digital transformation scenarios such as quality inspection, production line inspection, and airport ground handling.

In order to better serve customers, the excellent durability and stability of Seuic 5G industrial tablet also meet the requirements of efficient operation in harsh environments, greatly reducing maintenance times and costs.

Seuic's thin and light 5G industrial tablet has a wide range of application scenarios, and is committed to solving customers' pain points in data collection and inventory management in production, logistics and other links, and improving enterprise production efficiency and management efficiency.

- Unlocking Efficiency at China Eastern Airlines with RFID Technology2024-10-25

- How RFID Technology Boosts Textile Manufacturing Efficiency2024-10-24

- Streamlining Omron's Warehouse Management with Seuic Mobile Computers2024-09-26

- Revolutionizing Ticket Management for FIFA Events with AUTOID 10 Mobile Computer2024-09-12

- Foxconn Enhances Production Efficiency and Cuts Costs with Seuic's Scanning Solution2024-08-20